Cutting list optimization

Optimo

Optimo

Production with low scraps

Optimo was created to manage the production of both civil, and public works. The system allows different optimization solutions depending on the final product.

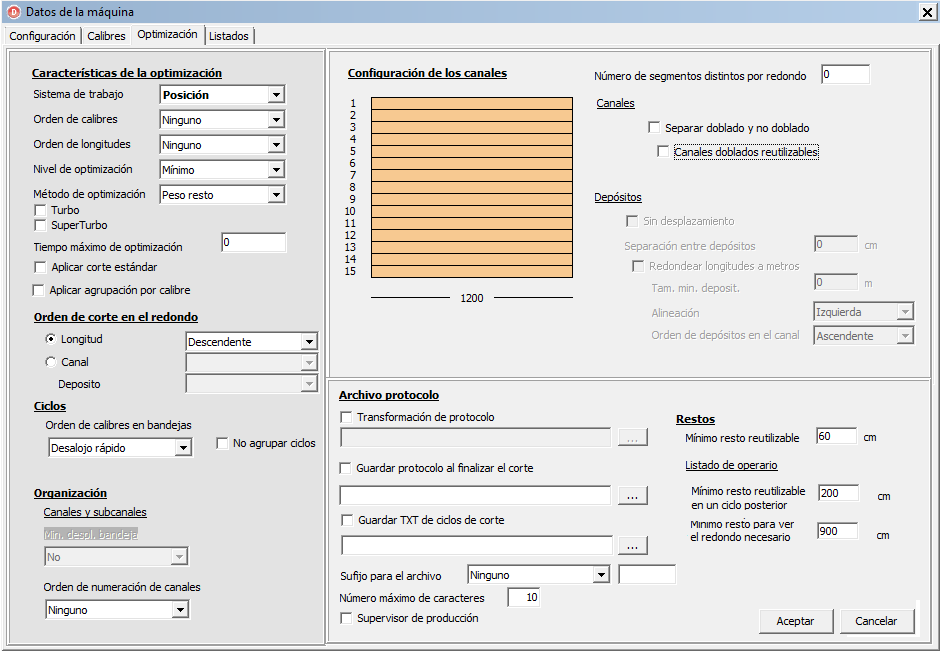

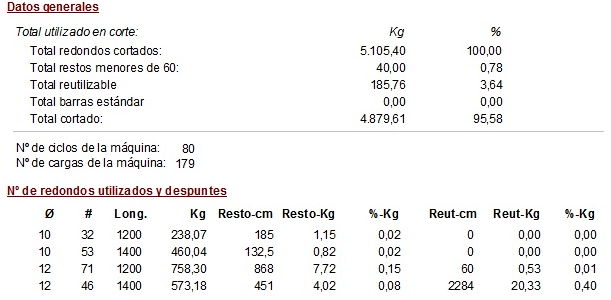

Optimo optimizes the machine’s space distributing the bars in different compartments, it minimizes the amount of scraps, it reduces the cutting cycles, (optimization of the cutting times), it optimizes the diameter change, it orders the cuts in the most convenient way according to the machine capacities, etc. Optimo is also an analysis tool, with which you can create multiple optimizations, evaluate our rebar shop and improve the production system.

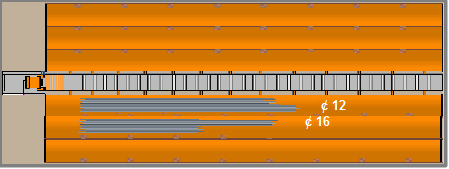

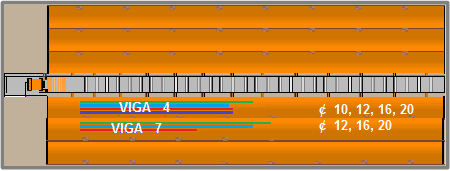

Cutting system by diameter

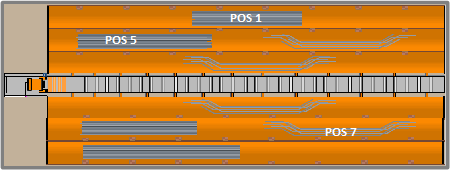

Cutting system by position

It optimizes the production order by placing the various positions in the available compartments.

It is advisable to use the machine with a minimum of 5 compartments with deposits to optimize an average of 9 or 10 positions simultaneously.

For a Barwiser it is needed a 7 compartments carriage to get the best optimization.

Ideal for public works where the final product is the position in machines such as the Shearline, Optibat or Barwiser.

There are two types of cutting by location. They can be use for any order or machine.

Cutting system by element

It optimizes the production order by splitting the elements in the machine compartments.

We suggest you a machine with 10 compartments to have a good optimization. We recommend you a Barwiser 26 with 25 compartments for the best optimization.

Recommended for civil works where the final product is the element on machines such as the Barwiser.

The bars that make the element, with different diameters, are discharged in the same compartment. The element is the final product and it is identified by a label for each element.